|

|||||

|

|||||

|

|

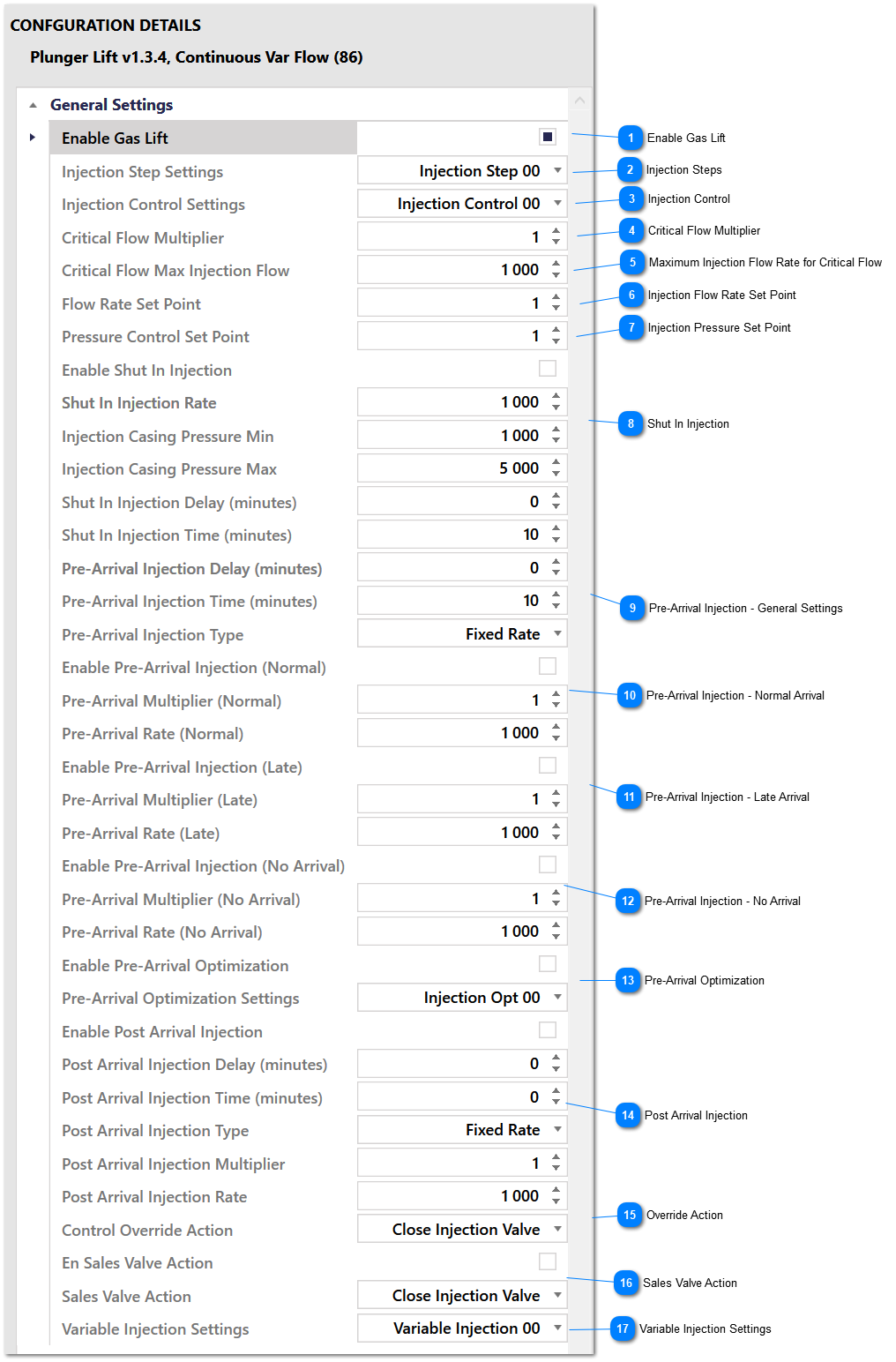

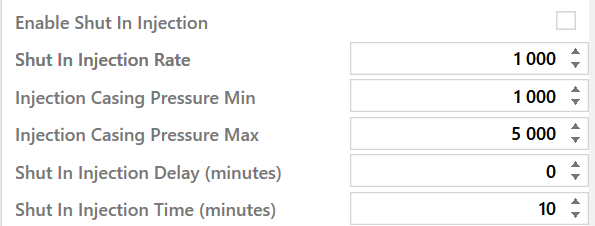

These settings are used to control shut in injection when the Gas Lift Control Mode is Plunger or when Gas Lift Control Override is enabled. In Plunger mode, if Enable Shut In Injection is selected, the program will wait until the Shut In Injection Time expires and then check if the actual casing pressure is less than the Injection Casing Pressure Min value when the plunger control algorithm enters the After Shut In Delay state.

If the actual casing pressure is less than the threshold, then shut in injection will start and continue until either the casing pressure exceeds the Injection Casing Pressure Max or the Shut In Injection Time expires.

When Gas Lift Control Override is enabled, these settings will be used to inject gas, but only if the Control Override Action is Shut In Injection. As long as the override is enabled and the action is Shut In Injection, the program will inject gas if the casing pressure is less than the Injection Casing Pressure Min value, and stop injecting gas if the casing pressure is greater than the Injection Casing Pressure Max. If the amount of time spent injecting exceeds the Shut In Injection Time, injection will stop and not start again regardless of the casing pressure.

When En Sales Valve Action is enabled, these settings will be used to inject gas when the plunger sales valve is closed, but only if the Sales Valve Action is Shut In Injection and the gas lift control mode is Continuous Flow or Continuous Critical Flow. The behavior is identical to that described above, where the control mode override is active.

| ||

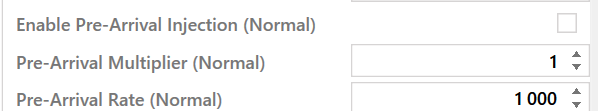

These settings are used to control pre-arrival injection when the Gas Lift Control Mode is Plunger. These settings are used if pre-arrival optimization is not enabled and the plunger arrival type for the last cycle was normal or early.

If Enable Pre-Arrival Injection (Normal) is selected, and the previous plunger arrival was normal or early, then gas will be injected at a rate that is determined by the Pre-Arrival Multiplier (Normal) or the Pre-Arrival Rate (Normal).

If the Pre-Arrival Injection Type is Fixed Rate, then gas is injected at the Pre-Arrival Rate (Normal). If the Pre-Arrival Injection Type is Critical Flow, then gas is injected at the calculated critical flow value multiplied by the Pre-Arrival Multiplier (Normal).

|

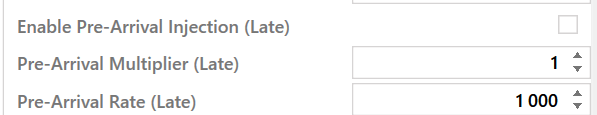

These settings are used to control pre-arrival injection when the Gas Lift Control Mode is Plunger. These settings are used if pre-arrival optimization is not enabled and the plunger arrival type for the last cycle was late.

If Enable Pre-Arrival Injection (Late) is selected, and the previous plunger arrival was late, then gas will be injected at a rate that is determined by the Pre-Arrival Multiplier (Late) or the Pre-Arrival Rate (Late).

If the Pre-Arrival Injection Type is Fixed Rate, then gas is injected at the Pre-Arrival Rate (Late). If the Pre-Arrival Injection Type is Critical Flow, then gas is injected at the calculated critical flow value multiplied by the Pre-Arrival Multiplier (Late).

|

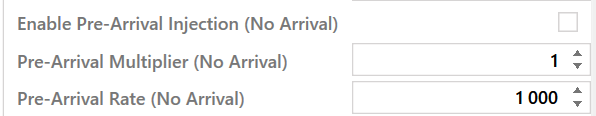

These settings are used to control pre-arrival injection when the Gas Lift Control Mode is Plunger. These settings are used if pre-arrival optimization is not enabled and the plunger did not arrive in the last cycle.

If Enable Pre-Arrival Injection (No Arrival) is selected, and the plunger did not arrive in the previous cycle, then gas will be injected at a rate that is determined by the Pre-Arrival Multiplier (No Arrival) or the Pre-Arrival Rate (No Arrival).

If the Pre-Arrival Injection Type is Fixed Rate, then gas is injected at the Pre-Arrival Rate (No Arrival). If the Pre-Arrival Injection Type is Critical Flow, then gas is injected at the calculated critical flow value multiplied by the Pre-Arrival Multiplier (No Arrival).

|

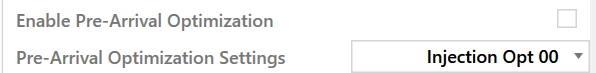

These settings are used to control pre-arrival injection when the Gas Lift Control Mode is Plunger.

Select Enable Pre-Arrival Optimization to allow the program to automatically adjust the injection flow rate for pre-arrival injection. When this option is selected the injection flow rate will be determined automatically and the settings that use the previous plunger arrival type will not be used even if they are enabled.

Use the Pre-Arrival Optimization Settings parameter to choose a set of options to control optimization.

|

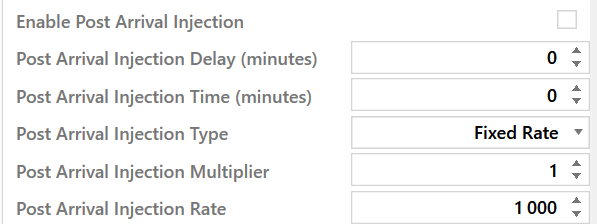

These settings are used to control post-arrival injection when the Gas Lift Control Mode is Plunger. Use these settings to control gas injection after the plunger arrives.

Select the Enable Post Arrival Injection option to inject gas after the plunger arrives. Gas injection will not start until the Post Arrival Injection Delay expires and will continue until the Post Arrival Injection Time expires or the well is shut in.

If the Post Arrival Injection Type is Fixed Rate gas will be injected at the Post Arrival Injection Rate. If the Post Arrival Injection Type is Critical Flow then gas will be injected at the calculated critical flow rate multiplied by the Post Arrival Injection Multiplier.

If the Post Arrival Injection Type is Continuous Variable Flow then gas will be injected at a rate determined by the output of a PID that is configured using the Variable Injection Settings. Note that the critical flow multiplier is set via the Variable Injection Settings when in this state. See the Continuous Viable Injection section on the Gas Lift page for more details. Note

|

|

Use this setting to choose what happens when Gas Lift Control Override is enabled. However, if the gas lift control loop is not enabled no action will be undertaken when the override is enabled. If the selected option here is Shut In Injection, the shut in injection settings will determine how gas is injected.

|

Use these settings to change the behavior of the gas lift program when the plunger sales valve is closed. These settings only apply when the gas lift control mode is Continuous Flow or Continuous Critical Flow. In other gas lift control modes these settings have no effect.

Choose the En Sales Valve Action to allow the program to change how gas is injected when the plunger sales valve is closed. When the En Sales Valve Action is not selected, then the gas lift program will operate according to the configuration and selected gas lift control mode.

Use the Sales Valve Action setting to configure what happens when the plunger sales valve is closed, En Sales Valve Action is selected, and the gas lift control mode is Continuous Flow or Continuous Critical Flow. The Close Injection Valve option forces the injection valve closed. The Shut In Injection option uses the shut in injection settings to automatically start and stop gas injection based on the measured casing pressure in the well.

When the plunger sales valve is open no action will be undertaken and gas lift will operate based on the configuration and the selected gas lift control mode.

|